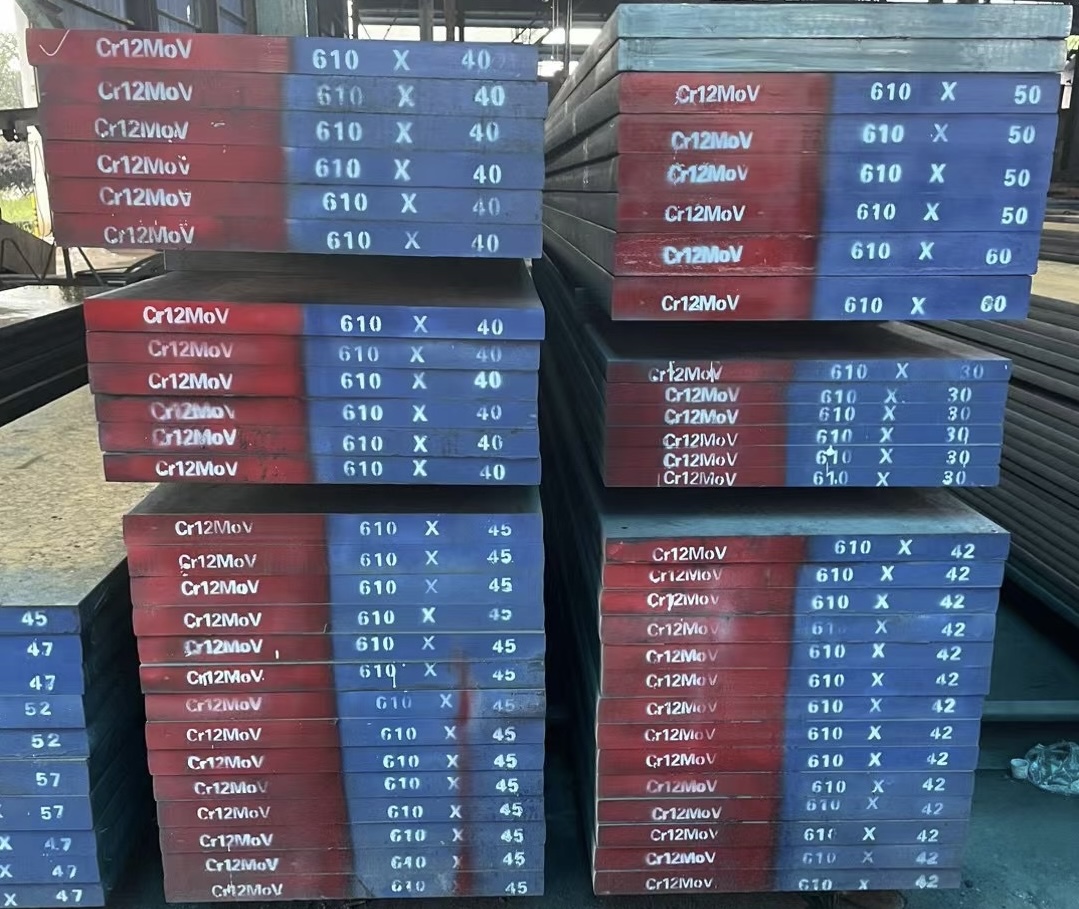

D5 mould steel has higher hardenability, hardness, strength and toughness after quenching and tempering than D3. Workpieces with diameters below 300~400mm can be completely quenched, with small quenching deformation, but poor high-temperature plasticity. D5 is mostly used to manufacture composite molds and tools with large cross-sections, complex shapes, and heavy workloads. Such as punching die, trimming die, rolling die, steel plate, etc.